Product overview

The state-of-the-art electromagnetic clutch and brake solutions we provide are shaped by our work with customers and are designed to fit the precise specifications for applications within the construction and material handling sectors.

These electromagnetic products are predominantly compact, high torque solutions, developed to suit a range of applications.

| ELECTROMAGNETIC CLUTCHES AND BRAKES RANGE | |

|---|---|

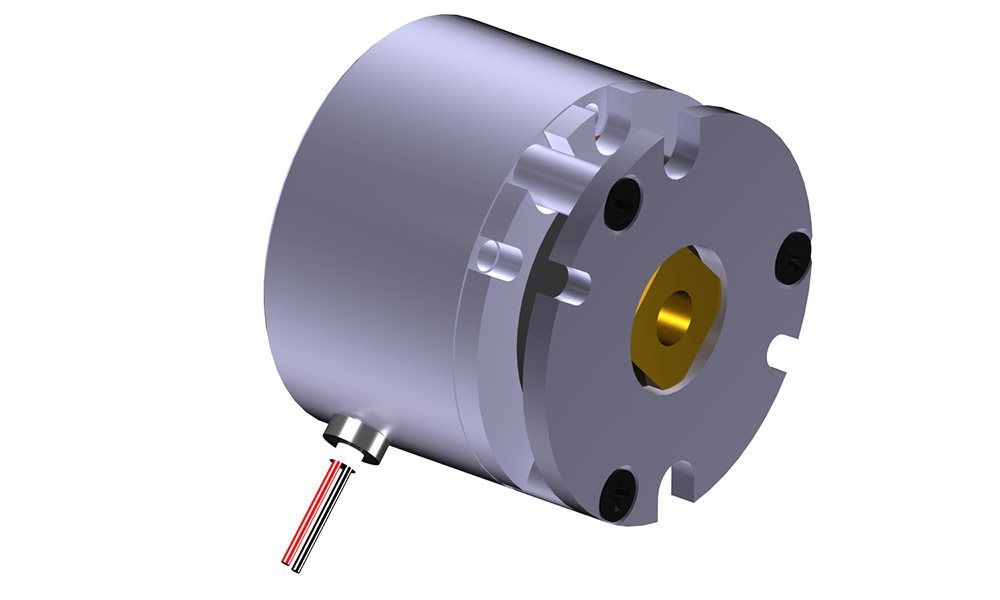

| Spring-applied failsafe | Electromagnetic release spring applied brakes. Engaging when electrical power supply is removed. |

| Failsafe | |

| Available as single and multiple-disc friction face options | |

| Compact size, high torque | |

| Optional voltages | |

| Flange and shaft mounted options | |

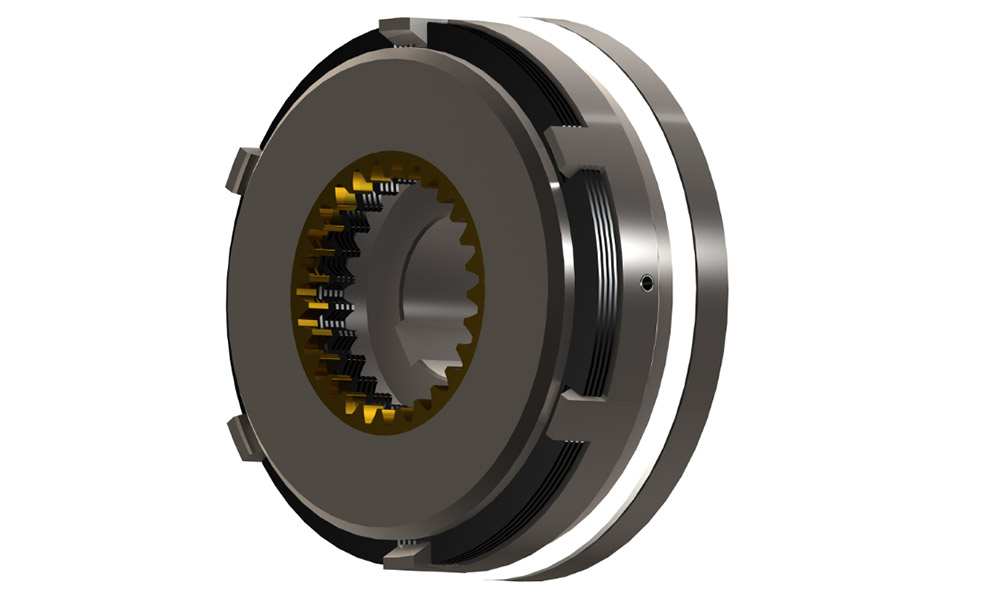

| Toothed | High torque |

| No slip | |

| Power on engagement | |

| Flange and shaft mounted options | |

| Permanent Magnet | Permanent magnets keep the clutch engaged should power fail |

| Compact size, high torque | |

| Flange and shaft mounted options | |

| Load per wheel | up to 7257 kg |

| Bespoke Electromagnetic solutions | Designed and manufactured to suit customer specification |

| EM Clutch capacity range | Transmitting Torque Range: 0.2Nm – 40000Nm |

| Rated Dynamic Torque Range: 0.5Nm – 10000Nm | |

| EM Brake capacity range | Transmitting Torque Range: 0.1Nm – 40000Nm |

| Rated Dynamic Torque Range: 5Nm – 10000Nm | |

| Voltage | 24V – 205V |

Product advantages

- Failsafe permanent magnetic clutch, with remote switch operation

- Provides a compact, lightweight solution

- Flange and bearing mounted options

- Can be designed to customer specification

Sectors

Product applications

- Pumps and compressors

- Packaging and processing

- Conveying

- Vibrator/exciter drives

- Mixing

- Turf cutters

- Ground aerators

- Wood chippers and logging machines

- Fire & security

- Recreation

- Groundcare