Product overview

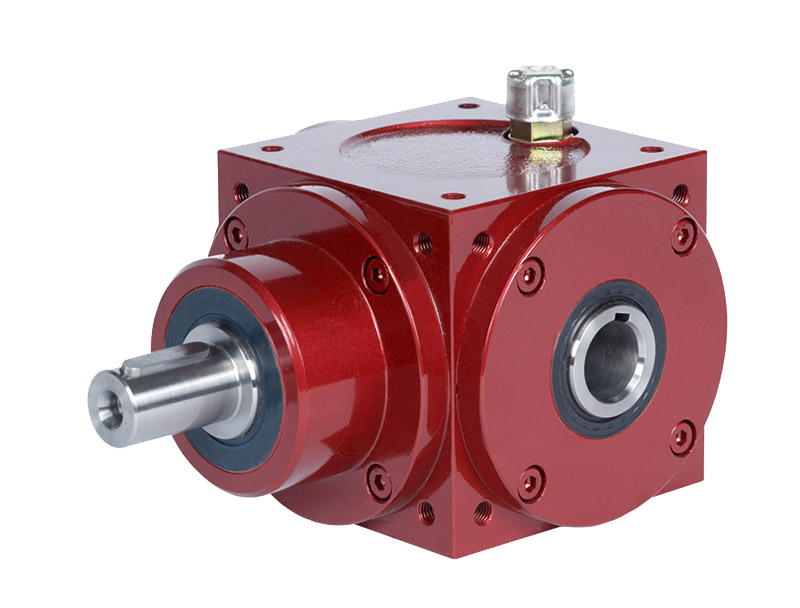

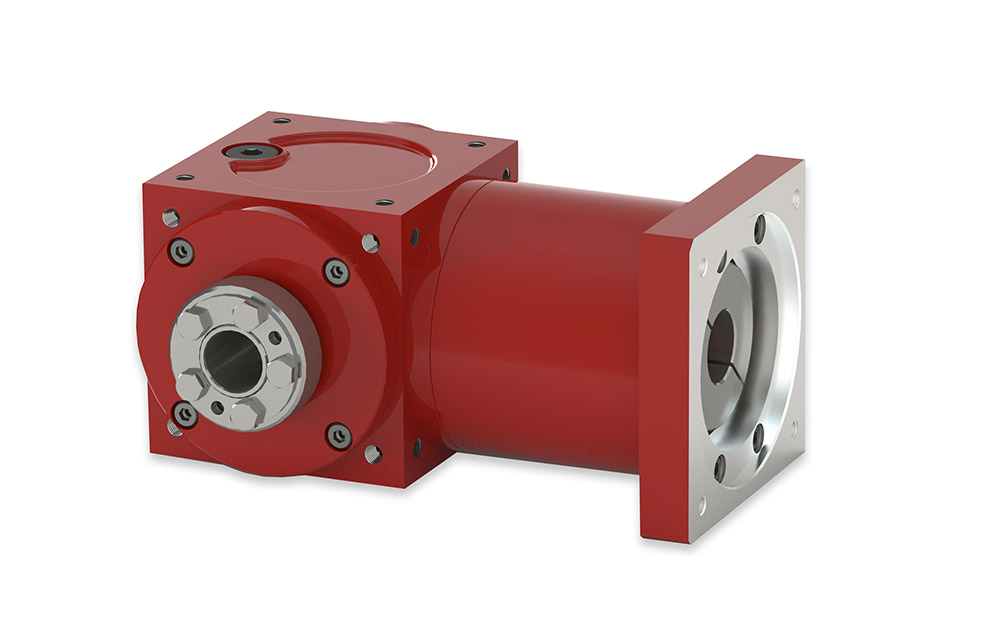

Bevel gear units are commonly used where a directional change in the transmission or torque split is necessary.

These solutions are versatile enough to be used in a number of ways, and the bevel gears we supply are manufactured for unbeatable longevity. Using our extensive technical expertise, we can also adapt bevel gears to suit the individual requirements of your application.

Our range includes ZAE bevel gear units and among these products is a pioneering solution manufactured from stainless steel and capable of resisting the effects of cleansing agents.

Boasting smooth polished housing surfaces that prevent the build-up of bacteria and dirt, our bevel gear drives are the perfect solution for the food, beverage, chemical and pharmaceutical industries. If you’re looking for a specialist gearbox solution, we’re also able to offer a low backlash option for servo motors: this is available across our full range of bevel gears.

| BEVEL GEAR UNIT RANGE | |

|---|---|

| Bevel Gear Units | Standard ratios ranging from 1:1 to 4:1, with special ratios available on request |

| < 2,400Nm output torque capacity | |

| Stainless steel options available | |

| Low backlash option for servo motors | |

| Bespoke Bevel Gears | Designed and manufactured to suit customer specification |

Product advantages

- Robust case-hardened gears, housed in rigid cast iron or stainless steel

- Spiral bevel gear teeth for optimal power and low running noise.

- Compact right-angle drive, boasting various shaft outputs and motor mount configurations

- Optional directions of rotation available to suit a wide range of applications

Sectors

- Agriculture

- Aircraft Ground Maintenance

- Marine & Offshore

- Material Handling

- Packaging and Processing

Product applications

- Mixing

- Feed screws

- Indexing

- Polishing

- Pumps & compressors