Powertrain system integration & solutions

We are passionate about making an impact for the businesses we work with and which is reflected in our process. We embrace creativity and innovation, and are committed to continuous improvement throughout our business, for the benefit of our customers.

Our Process

From an initial idea to development, production and after-sales, Lancereal will be with you every step of the way. Here’s how we can work with you on powertrain integration and solutions…

Idea

We’ll liaise closely with you to scope out and determine your machine requirements, bringing our industry expertise into play

Design

We’ll collaborate with your engineering team, partnering with them to design an optimal solution .

Prototyping

We’ll supply products and software for prototype development, and troubleshoot any problems

Development

We’ll support product development, through optimising software and products for technical performance and cost effectiveness

Production

We’ll ensure on-time delivery and enable serial production, through working closely with the supply chain and managing stock

After-sales

We can source and stock spare parts, and we provide both warranty and post-warranty technical support

Working with you

We can enhance your team’s capabilities, applying decades of expertise in power transmission systems to fill knowledge gaps and keep projects on course.

We act as your full power transmission partner, taking the strain of component procurement away from you, and ensuring you only need to deal with one provider: this will save you time and resources.

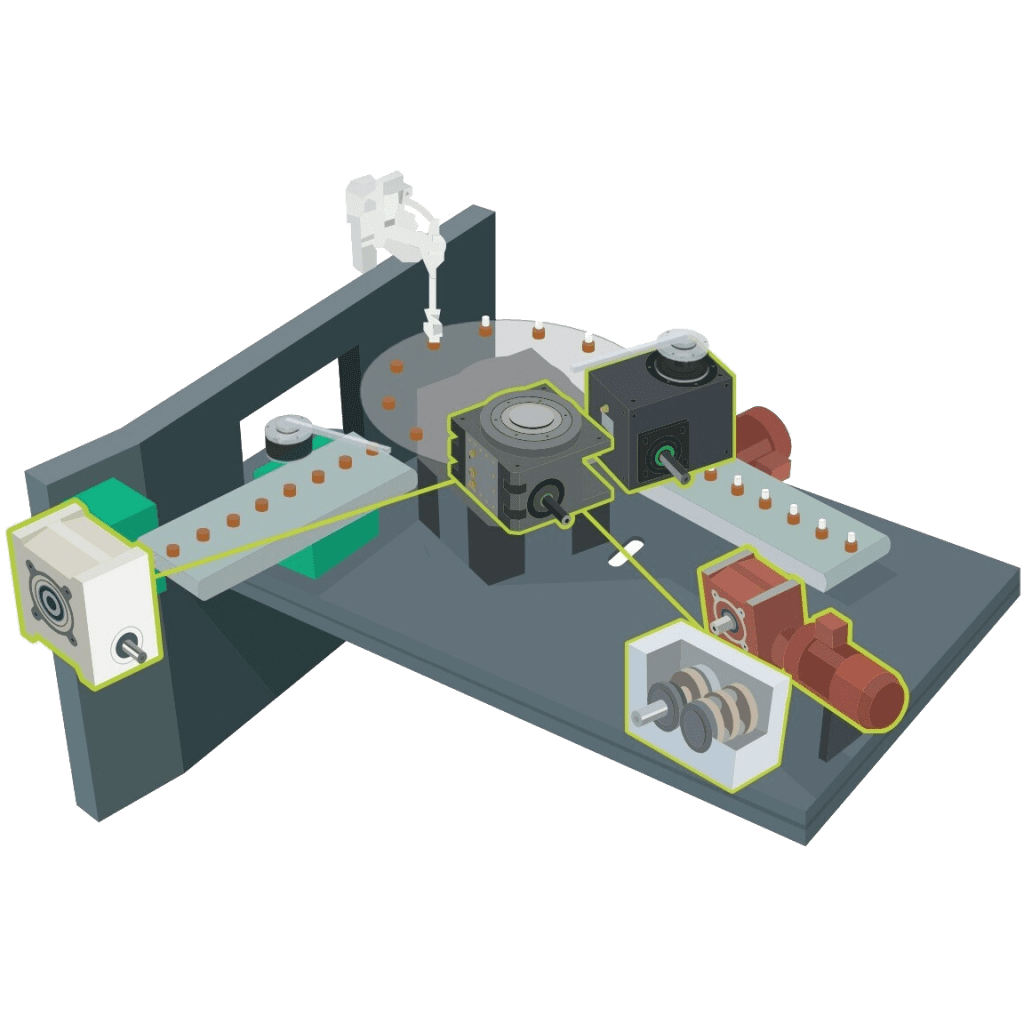

System integration

Our team can work closely with your engineers to identify and analyse requirements, and then design, prototype, develop and integrate complete power transmission systems. If you are kickstarting a project, we can input into the early design stages, and in conjunction with your team, steer a path to success.

Long-term support

Our commitment to each project extends far beyond its initial stages.

We can collaborate with your team throughout the entire product lifecycle, providing aftermarket support from repairs and maintenance to technical consultancy.

Case studies

Learn more about Lancereal’s extensive capabilities and how we’ve made an impact for customers.

Case studies

A Partnership with EXVO – Innovation in Electric Vehicle Technology

Client Overview: EXVO, a forward-thinking start-up specialising in electric-powered vehicles, turned to Lancereal for help in developing key components for its EX2 wheel-drive system. The focus of this collaboration was advancing the EX2 project from prototype testing to full production. As a new company, EXVO struggled to find a supplier…

Find out moreCase studies

Our Collaboration with Aldercote to Deliver a Bespoke Solution at Speed

Client Overview: Aldercote is a leading provider of vehicle-mounted access platforms, designing, engineering and building aerial work platforms for industries including telecoms, utilities, and local authorities. Aldercote prides itself on its speed to market – following an agile approach that sets the company apart from its competitors. But when Aldercote…

Find out moreCase studies

Fairfield Torque Hub

Lancereal Overhaul Fairfield Torque Hub From An Aerial Work Platform Lancereal support the aerial work platform aftermarket as the certified distributor and repair centre for Fairfield Torque Hub. The Fairfield Torque Hub is a well-known brand of planetary drive in the aerial work platform market. These gearboxes have been used by original…

Find out moreCase studies

On-Site Gearbox Repair

Lancereal Provide On-site Gearbox Repair To The Oil And Gas Industry Lancereal recently visited a customer site in Brazil to carry out the on-site gearbox repair of 8 gearboxes that required maintenance and upgrade work. As an authorised distributor for Fairfield Torque hub we support the manufacturers of industrial machinery…

Find out moreCase studies

Gearbox Maintenance Training

Gearbox Maintenance Training To A World Leading Oilfield Services Company We recently welcomed guests from one of our key customers, a global leader in oilfield services, for three days of hands-on gearbox maintenance training at our Huddersfield facility. The in-depth course tackled the fundamentals of transmission systems, including routine and ongoing maintenance…

Find out more